Overview

Extract surface curvature

Sheet metal part manufacturing requires higher accuracy and shorter lead times for bending processes that are flexible and effective. Understanding the sheet metal surface curvature would reduce the deformation and defect of fresh material that is pulled into the die opening. With the help of GOM ATOS compact 3D scanner, we can scan the sections and curves of the sheetmetal to extract values for surface analysis. These values are useful to detect the surface comparison, surface defect map and material thickness. After scanning, the scan data is imported in 3D reverse engineering software called Geomagic Design X. In the software, we can use the Loft wizard feature to create reference planes and cross-section to draw the surface of the sheetmetal and extract the curvature values. This sheet metal 3D model output is given to the customer in any CAD format.

WORKFLOW

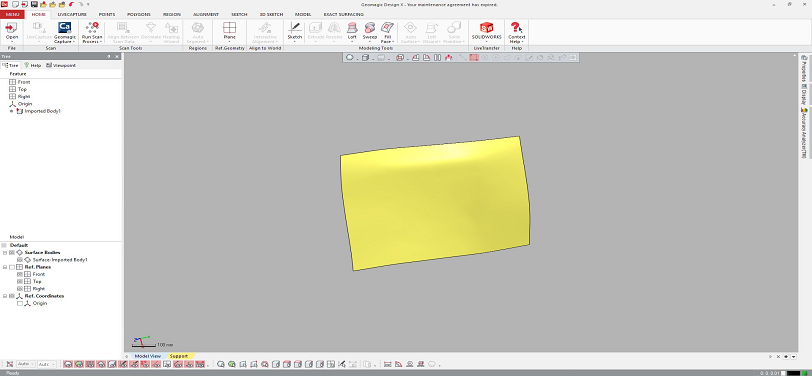

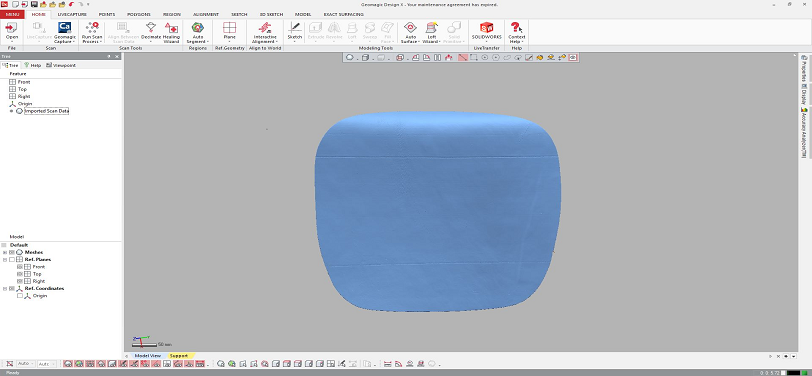

Import Surface.png)

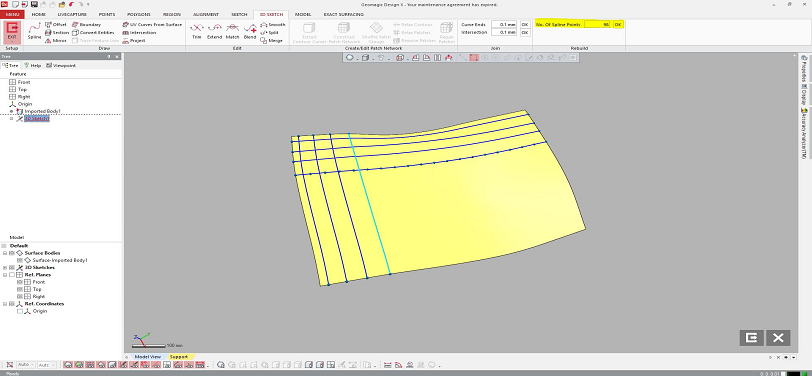

Import Surface

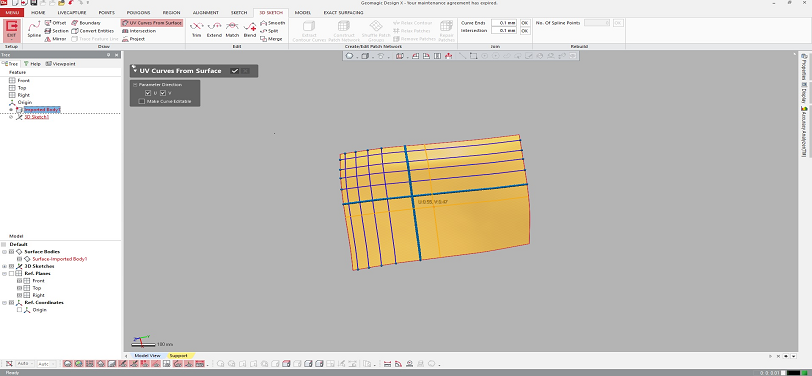

Using 3D sketch option to generate UV curves from the surface.png)

Using 3D sketch option to generate UV curves from the surface

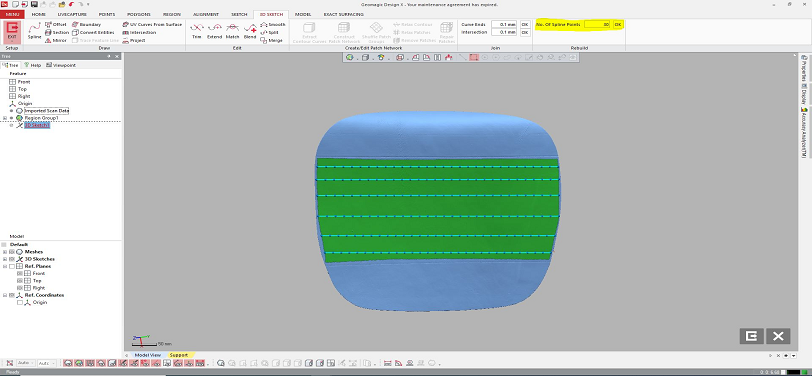

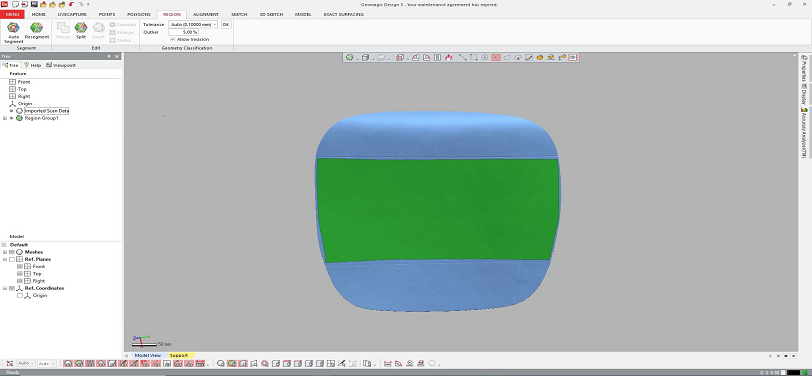

Pointing on the surface to select which area u need to create curvature on the surface.png)

Pointing on the surface to select which area u need to create curvature on the surface

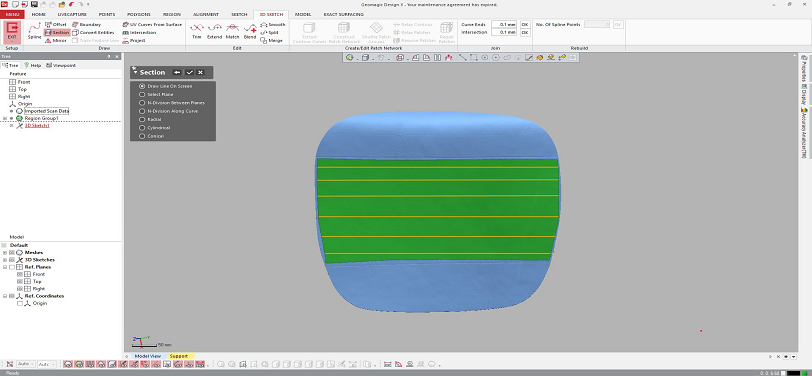

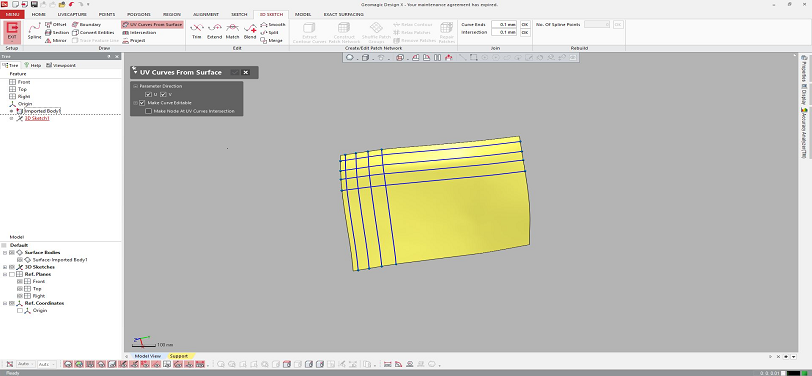

After creating 3D sketch we can change number of spline points whatever we required_.png)

After creating 3D sketch we can change number of spline points whatever we required

IMAGE

VIDEO

INDUSTRIES WE SERVE

WHAT'S NEXT?

RELATED BLOGS

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more