OVERVIEW

PRECISE3DM is India’s largest 3D printing service provider transforming Indian manufacturing Industries with its Digital Manufacturing solution. We use 3D Printing technology to manufacture end use parts that can be manufactured without involving tools or mould. We 3D print complex parts at low cost with fine geometrics directly from CAD Design. We manufacture your complex parts in a rapid Phase, You don’t have to wait for months. Our technology can manufacture the components in days, since we don’t use year old manufacturing methods. Our parts have exceptional strength, smooth finish, balanced weight, extreme accuracy compared to the manually fabricated parts.

KEY FEATURES

Our DM service is Ultra-Fast & Affordable, with same-day prototyping and low volume production without making any tool.

An alternative to traditional injection molding that enables designs to go straight from CAD to manufacturing without tooling or delay

We use 3Dsdsystems resin materials that are production and indirect production- grade and certified bio compatible and rapid prototyping materials.

The 3D printer is installed at technology partner locations in more than five places to cater to low volume production 3D printing service to pan India customers.

Traditional design restrictions do not apply anymore. Design complexity does not come at an additional cost during the production process with additive manufacturing techniques.

MATERIALS

We use high quality resins from 3D systems for our 3D printing service, The required components that are segmented into production grade, Indirect production and prototyping materials. Direct production materials are used to provide highly durable end use parts like thermoplastic and rubber, with six sigma certifications. We use Industry's best indirect production castable materials that are unique and most suitable for master prototype wax patterns to produce direct end use parts. Prototyping materials that we use have versatile properties that are essential for functional fitments, testing, and other prototyping applications.

MATERIAL GENERAL KEY FEATURES

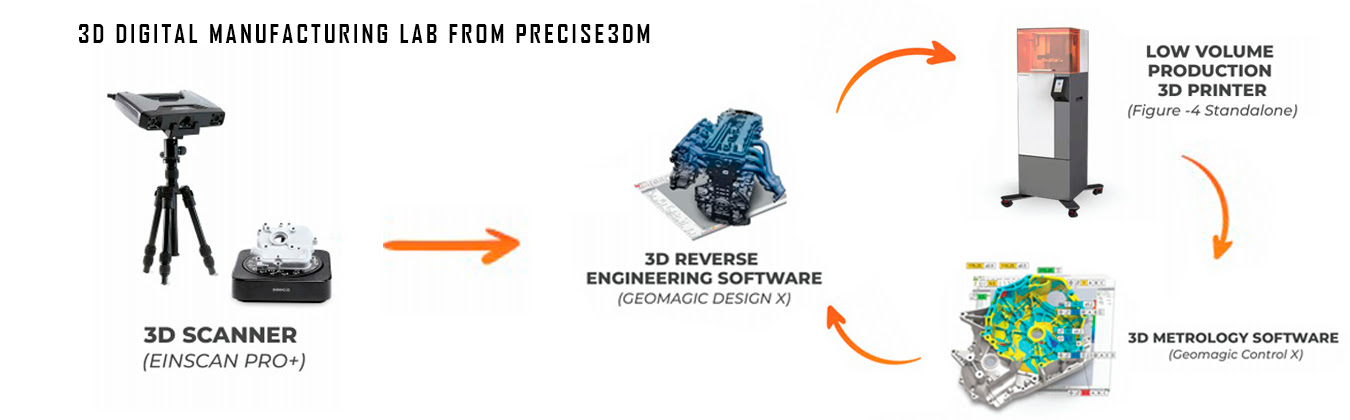

HOW IT WORKS

IMAGE GALLERY

Ear buds

Nut bolt

Jewellery

EngineeringPart

VIDEO GALLERY

CASE STUDY

What is Geomagic For Solidworks 2023 and Top 7 key features?

Key reasons why should you choose Freescan UE 11 3D Portable 3D scanner in India

3D scanning service in India 2023, why should you consider Precise3DM for your 3d scanning requirement in India?

Why is Geomagic Design X better than any other reverse engineering software in the market?

Vikram Movie uses 3D printing and 3D scanning technology for making Prop guns for movie scenes

What is a digital manufacturing Lab and how is it useful in the Education industry?

Are you an abroad client looking for a 3d scanning service in India? see how we help a French manufacturer

3D Scanning Service in India: A Guide for International Clients

FAQs

Is 3D printing as strong as injection molding?

We Precise3DM equipped with four Figure 4 offers some materials that are as strong as injection molded parts. Some of these materials provide tensile strength as high as 80 Mpa after proper post processing.

How can I avail 3D printing services in India?

We at Precise3Dm provide 3d printing services all over India. To use the services, you can contact us through our website or call any Precise3dm technical representatives.

What is the part size that you can do 3d printing and low volume production?

For general 3d printing, we can have a build volume of 300x300x500mm, and for low volume production, the build volume is 124.8 x 70.2 x 346 mm.

What technology do you use for 3d printing and low volume production?

We use DLP (Digital Light Projection) technology for low volume production. It has high print speeds that make it possible to print multiple parts in a realistic time frame

How long do you take to 3D Print my part?

Print time depends on the size and complexity of the part. To get an exact estimate of the time required to print your file, we would need a .stl file. You can directly upload your file on our website and get an estimate for time and cost as well.

My part is rubber. Do you print rubber-like material?

Yes!! We print rubber as well as many other production materials like bio-compatible materials and flexible materials. Our materials can effectively match the properties of some of the most used materials in production.

Per day how many parts can you print?

We use DLP (Digital Light Projection) technology for low volume production. It has high print speeds that make it possible to print multiple parts in a realistic time frame

How do you increase the strength of a 3D-printed part?

The strength of 3D printed parts can be increased by utilizing some post-processing measures like curing, for which we have special equipment. After curing, the properties of the material changes to some extent giving more strength to the materials