Overview

3D Scan alignments for CAD / CAM /CAE

Normally, the CAD part we import in the reverse engineering software does not have coordinate points initially, and they are called hanging coordinates. The purpose of digital alignment is to position the part, arrest the coordinates (0,0,0) points during any manufacturing or machining process so that the parts won’t move and be completely locked in a position. In Geomagic Design X, a feature called Align wizard is present, and it has different alignment modes. The first one is regional alignment in which regions are created in the geometrical features and positioning is made using the X and Y vector. This is also called segment alignment. The second method is Interactive alignment, which is a profile based sketch alignment. The hanging coordinates will automatically be fixed to (0,0,0) based on the sketch entities and if we move to any point in the plane, it will be fixed at the origin point only.

WORKFLOW

Import un Aligned mesh file.png)

Import un Aligned mesh file

Segmenting Feature regions on mesh.png)

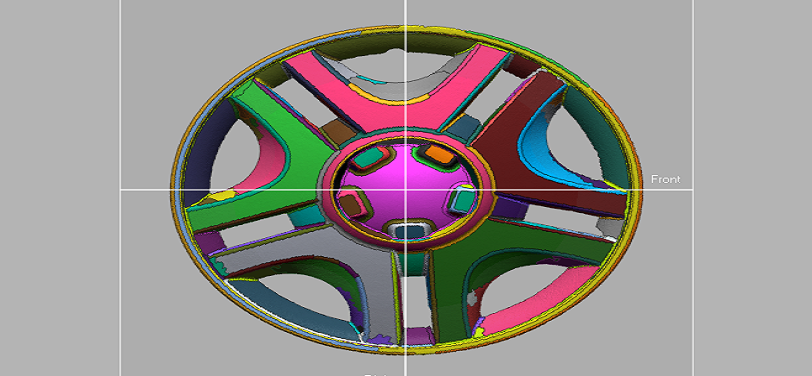

Segmenting Feature regions on mesh

Creating Reference Geometries.png)

Creating Reference Geometries

Alignment based on reference planes and vectors.png)

Alignment based on reference planes and vectors

Fully Aligned data.png)

Fully Aligned data

IMAGE

VIDEO

INDUSTRIES WE SERVE

WHAT'S NEXT?

RELATED BLOGS

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more

Scan To Parametric CAD

Parametric cad consists of a history-based feature modeling tree that can be edited to make design

Read more