PROCESS AND METHODOLOGY

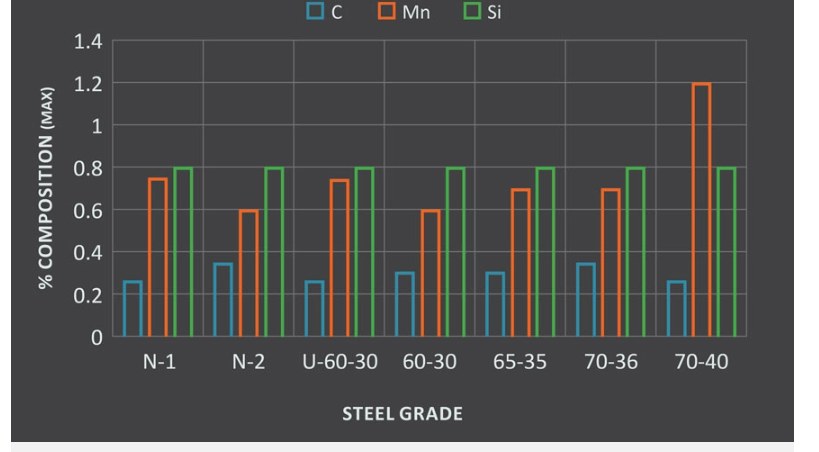

Material Grade

A metal grade is usually determined by its chemical composition, its mechanical properties, or both.

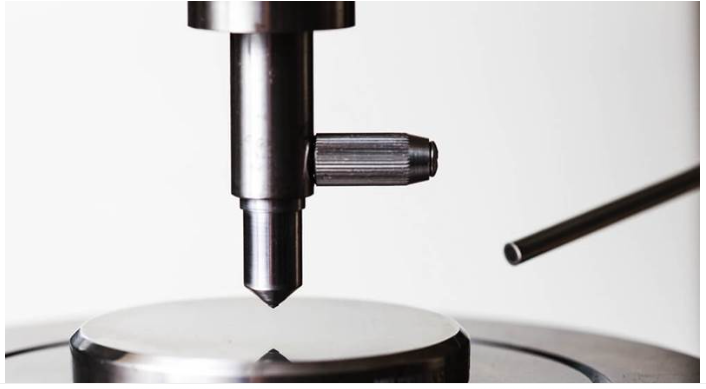

Surface Hardness

A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing

Coating thickness

A coating thickness gauge is a device used to measure the thickness of dry film, paint, rust, or any other material being applied as a secondary layer to a metal surface.