What is the cost of reverse engineering service in Coimbatore?

Our 3D Scanning Technology Partner Program offers a complete suite of 3D Scanning /Printing services by leveraging our in-house equipment at a discounted rate to the customer.

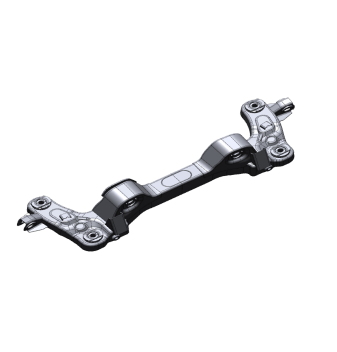

The cost of the reverse engineering service is based on components size and accuracy expectation, to be very approximate reverse engineering service in Coimbatore starts from 2000 inr.

Where can I get reverse engineering service in Coimbatore?

Precise3dm is the largest 3d scanning and reverse engineering service provider in Coimbatore. We are located in Ganapathy to enable in-house reverse engineering service in Coimbatore. We can also do on-site 3d scanning and reverse engineering in Coimbatore.

What is the difference between reverse engineering and 3D reverse engineering?

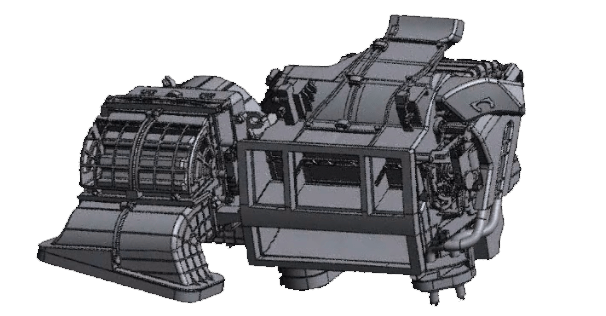

Reverse engineering means measuring the engineered parts manually and redesigning for manufacturing them again, whereas, in 3D reverse engineering, we perform 3D scanning instead of manually measuring. We use 3D scans as a reference to model the same.

Are 3D scanning and reverse engineering the same?

3D scanning and reverse engineering are two different terms. They are subsequent processes to make the duplication of any physical parts.

What are the file deliverables for reverse engineering service?

3D scanned models are designed and exported as IGES, STEP, SAT, AND Parasolid. We can also create history based files of Solidworks, Creo, CATIA and UG on demand.