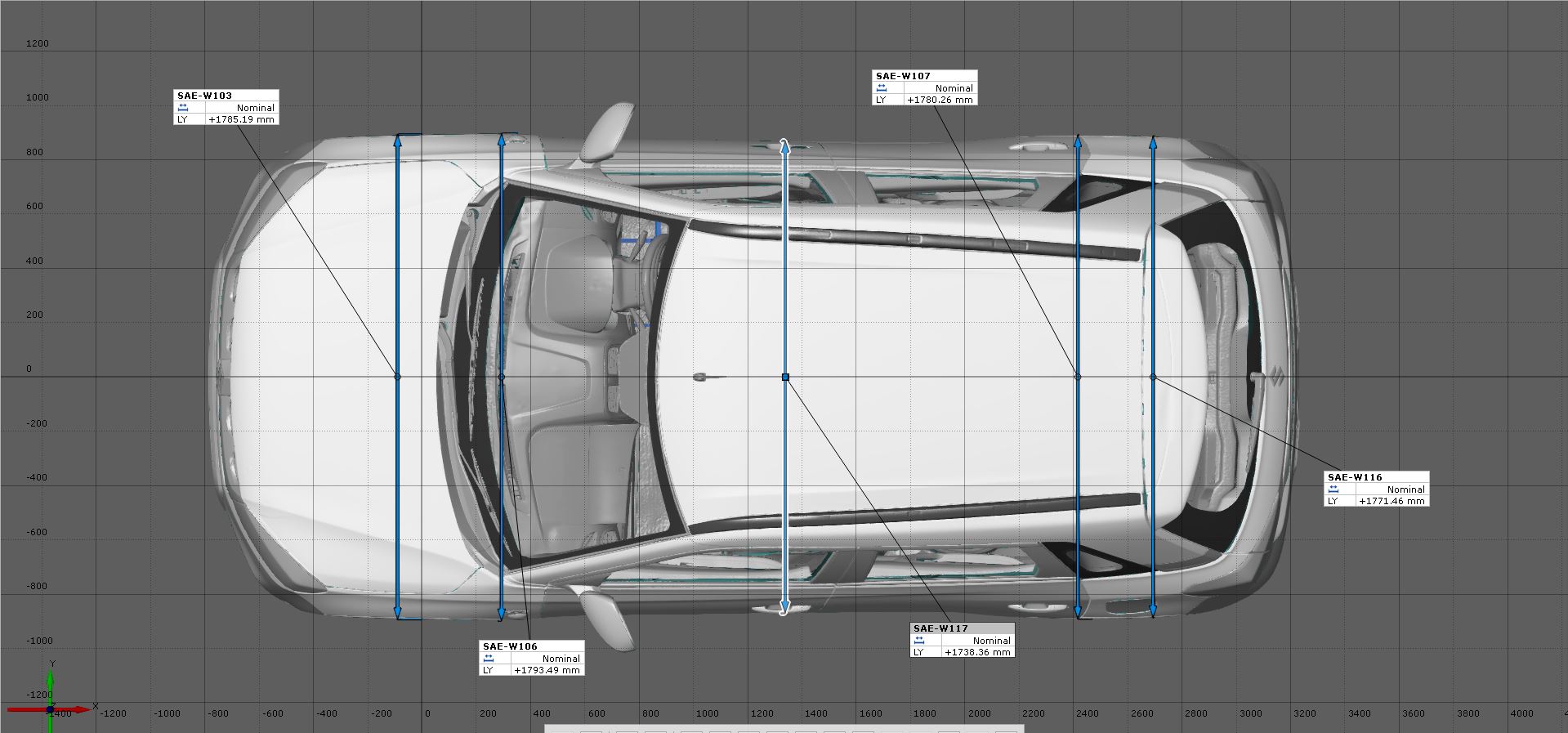

LWH Measurements

- Global car .stl is used to measure theses measurement’s

- Global vehicle exterior and interior standard measurements are taken from SAE j1100.

- More than 100 standard measurements are taken for vehicle dimension analysis such as wheelbase, vehicle length, Approach angle, departure angle, axle width, body width, step height, parking clearance height, belt height, etc.

Deformation analysis

- Scanned data of vehicle at variable weight conditions like a curb, GVWR to analyze how much the vehicle is lowered in variable weight conditions it is analyzed in digitally

- The deflections are measured with floor to curb and GVWR.

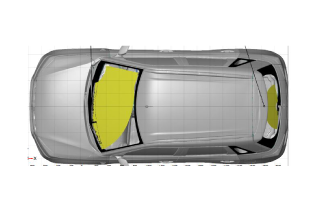

Surface Area Measurements

- In surface area measurements we measure

- Front & rear windshield area,

- Windows area, quarter glass area,

- Wiper swiping area, cargo floor area,

- Footprint area of the vehicle,

- Black ceramics, dotted area.

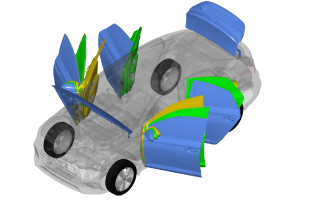

DOF Analysis

- In DOF analysis we measure the angle of the dot parts we have scanned.

- In Exterior additional scans we do(Doors in two or three opening positions, orvm closed positions, wiper sweeping area, black ceramics & dotted area, Fuel opened position )

- In interior additional scans we do (Seat tracking, seat positions, gear positions, steering positions, handbrake positions, glove box opened, sun visor positions, arm rest position, sunglass holder position)

Turning Radius Analysis

- In these, we analyze the turning radius of the vehicle

- This measurement is done from the .stl we have scanned in digital benchmarking

- The turning radius of the car is calculated digitally and further, it is analyzed for comparisons of vehicles.

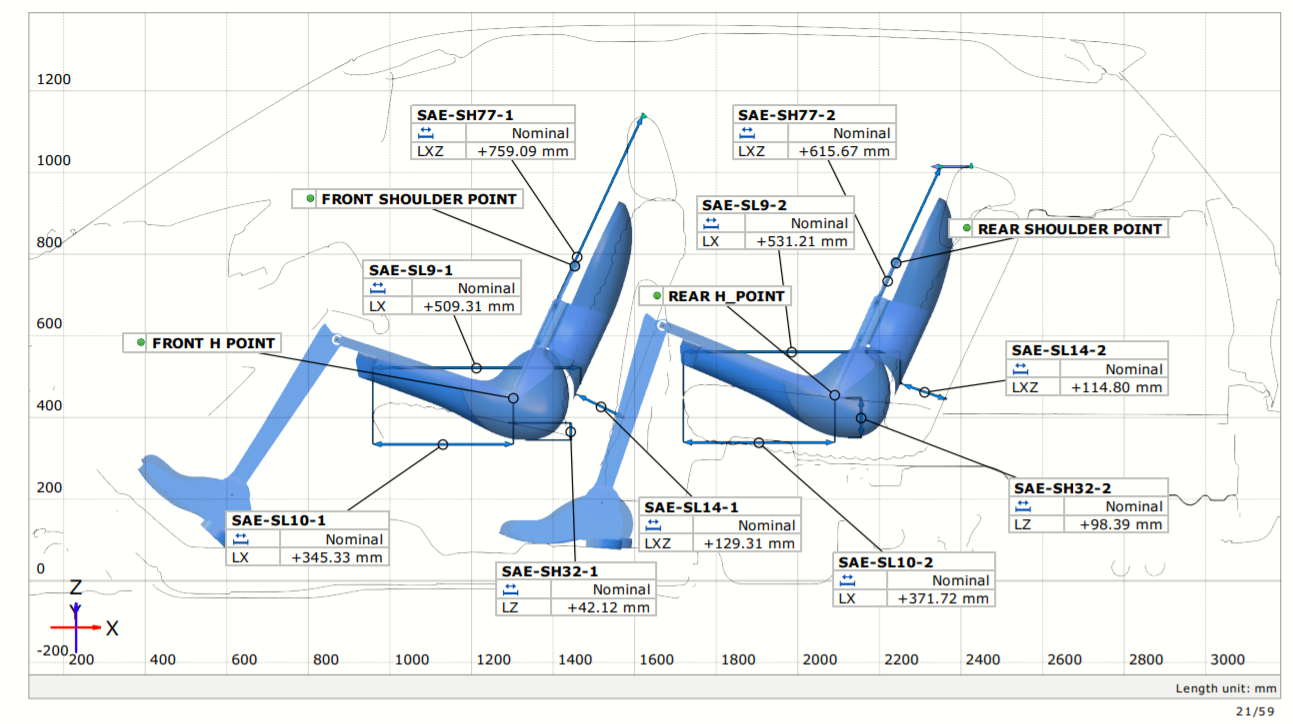

Ergonomic studies

- In ergonomic studies, we measure the vehicle interior details like

- Analysis of seat accommodations and their tracking positions, occupant’s headroom, legroom, driver vision area, H points, interior positions all are measured. 95th percentile CAD manikin is used to measure these measurements according to SAE J826 & J1100.

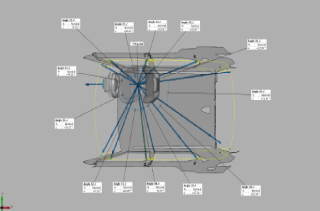

Driver vision angle assessment

- In driver vision, angle assessment driver’s blind spots angle is calculated and it is used for comparing with other vehicles

- Vision angle assessment calculating from the H-point to all the pillars in the driver aspect at an eye ellipse point.