PROCESS AND METHODOLOGY

IMPORT ASSEMBLY 3D SCAN FILES

- Using GOM blue light scanner for scanning the entire BIW Web

- Importing assembly scan data in .stl format

CREATING COORDINATE SYSTEM

- Creating coordinate system based on BIW Profile & Feature

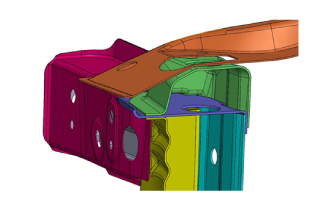

CREATING CAD FOR ASSEMBLY

SCAN DATA

- Develop outer skin design of the entire BIW assembly from the scan data

BIW TEARDOWN

- Our experts will do physical teardown of BIW for separating panels & parts based on the subsystem.

IMPORTING INDIVIUAL PART SCAN DATA

- Using GOM blue light scanner to scan the individual parts.

- Importing & aligning individual panels & parts scan data to the assembled scan data based on profiles and features

CREATING CAD OF INDVIUAL PANELS & PARTS

- Developing design of individual part features and profiles based on the scan data.

INTERFEREANCE ANALYSIS

- Interference and mating surface analysis on assembled CAD data.

ACCURACY ANALYSIS

- Ensure the perfect surface of BIW scan data to CAD data

EXPORT CAD DATA

- Export either as individual file or assembly file based on customer requirements.