VEHICLE ASPECTS

- Detail pictures of vehicle exterior, interior, underbody, engine compartment, boot area, the infotainment system in detail, cluster information’s in variable conditions, suspensions, special features, etc.

- Inspecting the gap and flush between each door and body of the car using step and gap gauge & Thermo taper gauge.

- Measuring LWH of the vehicle, volume measurements on storage areas in the driver cabin.

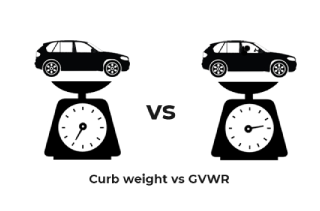

Weight Analysis

- Curb weight:Measuring the weight of the vehicle without any passenger or items in it except for the standard equipment that comes with it and consumables at levels.

- GVWR Weight:Measuring weight of the vehicle is filled with all consumables at correct level & loaded with passengers and cargo the weight details are given in owner’s manual.

- Axle Loads: Finding the front and rear axle load difference from curb & GVWR weights.

Teardown Process

- Tool access: Before teardown, we have to ensure that there any special tools are required to dismantle in that vehicle

- Torque measurements: Measuring the torque of every bolts & nut before removing.

- Consumable extraction: Before starting teardown we have to extract all consumables in the car like (Engine oil, coolant, brake oil, transmission oil, wiper water, transaxle oil, ac gas)

- Physical teardown:Starting dismantling the components in system-wise. Measuring the weight, extracting the details of that system, and updated in the BOM.

Teardown Levels

- Level 1 Teardown-Sub system-wise teardown:Subsystem wise such as (bumper, powertrain, suspension, seats, doors, instrument panel, frontend, heating system, fuel)

- Level 2 Teardown–Part wise teardown: Teardown every child components in that system-wise tear-downed parts.

- Level 3 Teardown-Destructive teardown & BIW Teardown:In destructive teardown tear downing a BIW up to a single individual panel.

Data Mapping

- Full vehicle photography (.jpeg)

- Teardown photography (.jpeg)

- Part level photography (.jpeg)

- Schematics photos (.jpeg)

- Bill of Materials creation